This page provides step-by-step instructions on how to enter and edit Subpart Q Iron and Steel Production process unit information for units that are NOT monitored by CEMS.

Under Subpart Q, "process unit" types may include any of the following:

- Taconite indurating furnace

- Basic oxygen process furnace

- Non-recovery coke oven battery

- Sinter process

- Electric arc furnace (EAF)

- Decarburization vessel (see note below)

- Direct reduction furnace

In 2010, the information required for decarburization vessels applies only to argon-oxygen decarburization vessels. However, for 2011 and subsequent calendar years, the reporting requirements apply to other decarburization vessels used to refine molten steel with the primary intent of removing carbon content of steel including, but not limited to, argon-oxygen decarburization vessels and vacuum oxygen decarburization vessels. This amendment was finalized in October 2010 (75 FR 66434).

Step 1: Add a process unit

To add a process unit that is NOT monitored by a CEMS, find the UNITS table on the Subpart Overview page and click the link titled "ADD a Unit."

To later edit information you have entered to identify a process unit, click the edit icon or the Name/ID link located in the first column of the table.

To delete a process unit, click the delete icon or red “x” located in the last column of the table.

Click image to expand

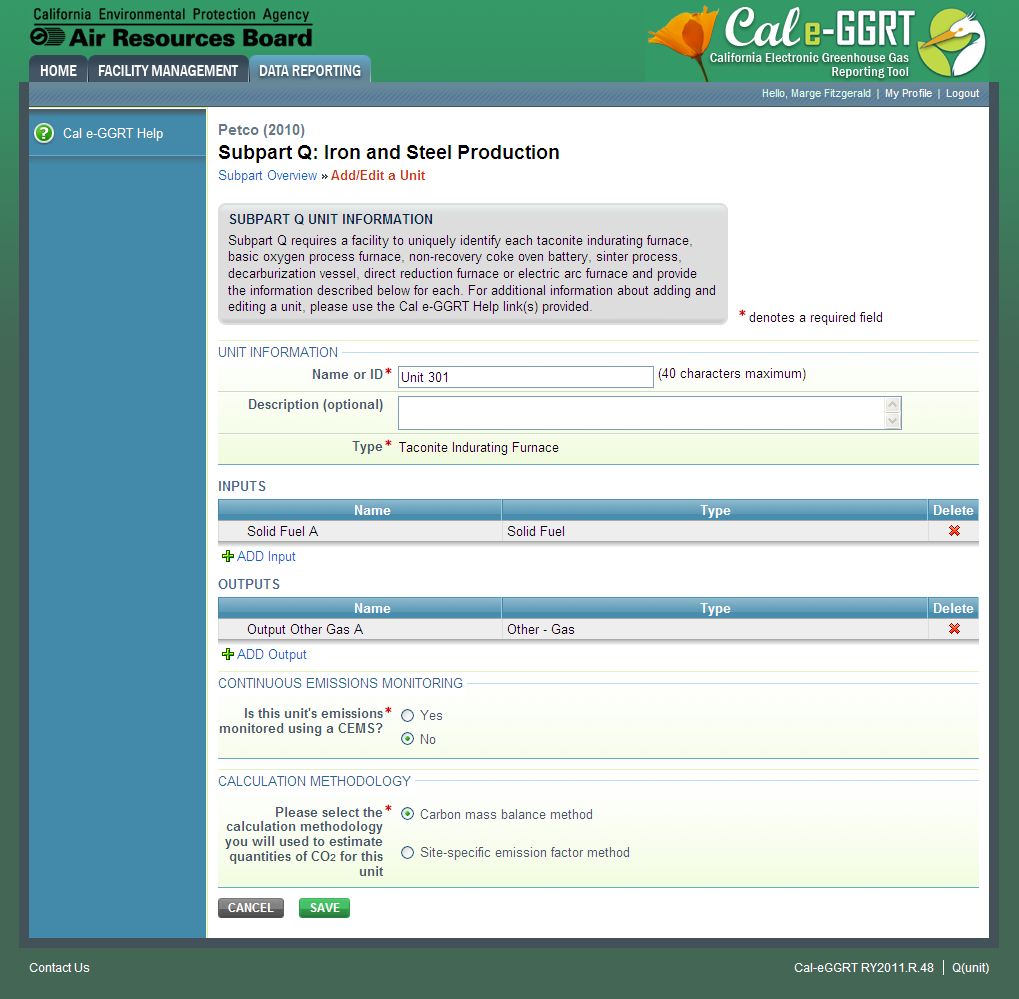

Step 2: Indicate CEMS utilization for the process unit

For each process unit, confirm whether or not the process unit utilizes CEMS.

Note that when adding a new process unit you are prompted to answer the CEMS question immediately (the answer to this question will default to “No” for process unit added using the “ADD a Unit” link and will default to “Yes” for units added using the “ADD a CEMS Unit” link).

The CEMS response may be changed here and the process unit information will be relocated to the appropriate table on the Subpart Overview page.

When finished, click SAVE.

Click image to expand

Step 3: Select calculation methodology

Use the radio buttons to indicate the calculation methodology used to estimate quantities of CO2 for this unit (Carbon mass balance method or Site-specific emission factor method)

When finished, click SAVE.

Click image to expand

Step 4: Define the process unit

For each process unit, enter the following required information:

- A unique name or identifier, plus optional description for this process unit

- The type of process unit, selected from the following:

- Taconite indurating furnace

- Basic oxygen process furnace

- Non-recovery coke oven battery

- Sinter process

- Electric arc furnace (EAF)

- Decarburization vessel

- Direct reduction furnace

- EAF/Decarburization Vessel Exhausting to Common Stack/Vent (applies ONLY if site-specific emission factor method is used to calculate CO2 emissions)

Step 5: Enter required input/output information for the process unit (if applicable)

Note that this step only applies if carbon mass balance method is used to estimate CO2 process emissions for this unit. If CO2 process emissions for this unit are estimated using the site-specific emission factor method, you may skip this step and proceed to Step 6.

To add an input or an output, click "Add an Input" or "Add an Output" below each respective table.

Click image to expand

For each input or output associated with the process unit, Subpart Q requires you to report the following information:

- A unique name or identifier

- The type of input or output selected from the following list (Note that the list will be customized in Cal e-GGRT to reflect the key inputs and outputs identified in the rule equations for a given type of process unit):

-

- Molten Iron

- Ferrous Scrap

- Flux Material

- Carbonaceous Material

- Other - Solid

- Other - Liquid

- Other - Gas

- Output types:

- Slag Produced

- Molten Steel Produced

- Air Pollution Control Residue

- Other - Gas

- Other - Liquid

- Other - Solid

-

When you are finished entering the required information for an input or output, click SAVE. Note, if you are using the carbon mass balance method, you must identify inputs and outputs associated with each process. If you do not, as a reminder you will see a data completeness validation message on the Validation report page as a reminder that you have not completed Unit-Level data entry.

Click image to expand

Repeat this step until all inputs and outputs associated with the process unit have been added and defined, then proceed to Step 6.

Step 6: Save all entered information for the process unit

When you are finished entering all required information for the process unit, click SAVE.

Click image to expand

Step 7: Repeat Steps 1-6

Repeat Steps 1-6 until all process units NOT monitored by CEMS have been added for your facility.

See Also

Screen Errors

Using Cal e-GGRT to Prepare Your Subpart Q Report

Subpart Q Process Unit Information for Units NOT Monitored by CEMS

Subpart Q Process Unit Information for Units Monitored by CEMS

Subpart Q Coke Pushing Operations Information

Subpart Q Flares Information

Subpart Q Emissions Information for Units NOT Monitored by CEMS

Subpart Q Emissions Information for Units Monitored by CEMS

Subpart Q Emissions Information for Coke Pushing Operations

Subpart Q Emissions Information for Flares

Subpart Validation Report